Increasing the ability to collaborate remotely ensures the integrity of the design.

Similar to Google docs, this feature allows for collaboration to be far more seamless. Smart P&IDs are more collaborative in nature as they are able to notify team members of any changes that occur in the design. Additionally, having the ability to account for any discrepancies early in a P&ID design process offers more security in the integrity of the final product. While designing, smart P&IDs alert and ensure users of discrepancies in any sort of fitments, compatibility, and construction issues. Unlike conventional P&IDs, smart P&IDs are able to ensure fitment and the integrity of the P&ID process. Thus users have a more accurate and easily compiled P&ID. This reduces bueracracy and paperwork, provides a single repository of relevant information, and streamlines P&ID creation. Smart P&IDs speed up the design process as it allows a single location to access all aspects of a P&ID. The data may be associated to the design, materials, and construction of a piping system. Having the smart P&ID automatically organize data associated with certain components of a system save the designer a lot of prep time. Unlike standard P&IDs, smart P&IDs are able to reference and ensure implementation of data given. Smart P&IDs automatically cross reference drawings, data, and documents associated with a design making them the ideal option for design.Īdvantages of a Smart P&ID Organizes Related Data Courtesy: Environmental Intellect Because of their active nature, smart P&IDs speed up the process of creating a piping system.

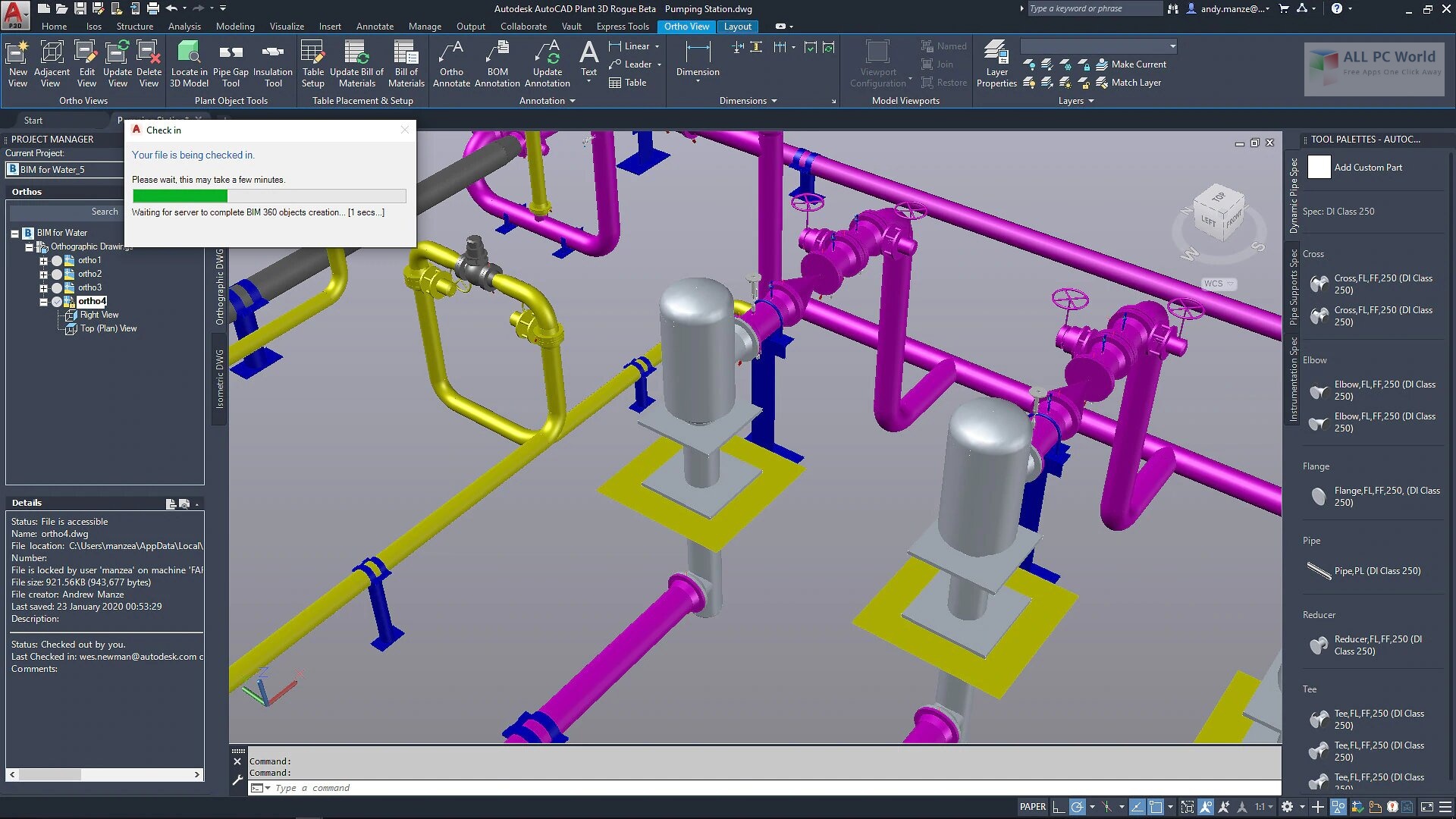

Smart P&IDs also actively update data used to create a P&ID when they change in the design, streamlining the process. Often times, non-intelligent P&IDs are two dimensional, where smart P&IDs may utilize CAD programs to generate more intelligent and design-conscious P&IDs that are more representative of the physical design. Additionally, smart P&IDs may be linked to other data bases such as INFOplant to continuously offer improvements and suggestions to existing P&IDs. Comparatively, a traditional P&ID would allow a user to place a component in a design without justification whereas a smart P&ID references equipment data sheets, component sizing, and other specifications to ensure a working design. Smart P&IDs take a step up from traditional P&IDs as they add computer-based intelligence into the design process.

0 kommentar(er)

0 kommentar(er)